Sound proof fully insulated enclosure!

Reducing Noise Pollution for Impregnation Services with the SE Series Sound Reducing Kit

Challenge:

Protecting Operators from Excessive Noise from a Dot Peen Marking Machine

Impregnation Services, a local leader in casting porosity sealing, encountered a significant challenge with their dot peen marking machine. This machine, essential for engraving serial numbers and part identifications, produced a loud, high-frequency noise that could affect the health and well-being of their operators. With sound levels frequently exceeding safe limits, the company needed an effective solution to reduce the noise and create a safer working environment.

Objective:

The primary objective was to reduce the noise generated by the dot peen machine to ensure a safe and comfortable working environment for the operators, without compromising the machine’s performance. The goal was to achieve a noise reduction of at least 25 decibels, bringing the sound level within recommended limits.

Solution:

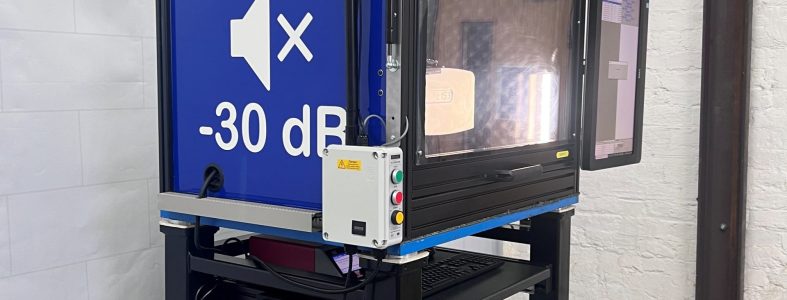

Impregnation Services reached out to us with their concerns, and we began a collaborative process to design a custom solution. After an initial assessment, it was clear that a soundproofing enclosure was the best approach to mitigate the noise. We chose our fully insulated SE Series, a safety enclosure with high density composite framework .

Development Process:

1. Initial Assessment and Design:

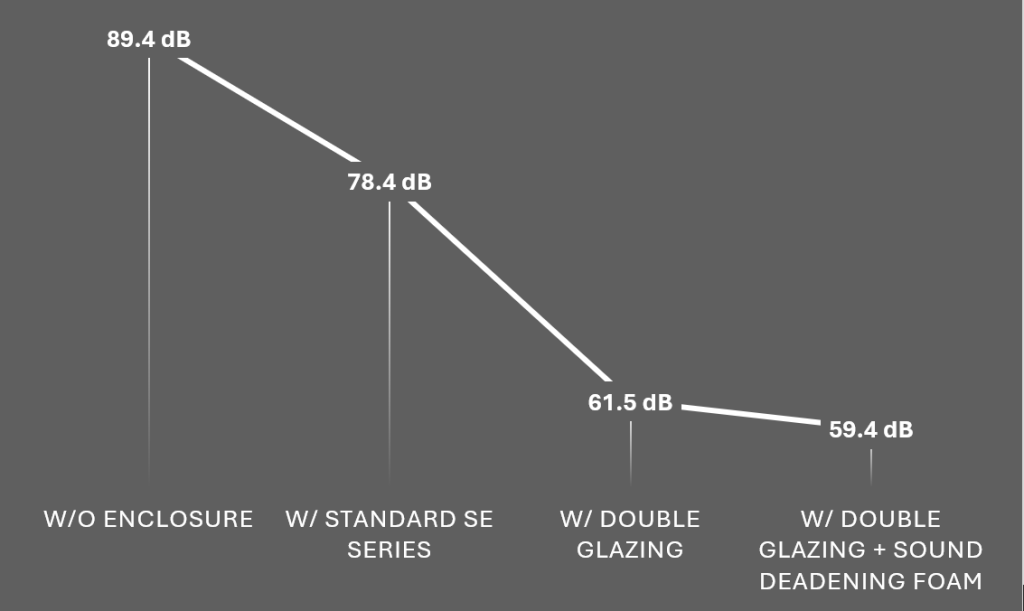

– Our team conducted a thorough analysis of the dot peen machine’s noise output, identifying the key frequencies and decibel levels which were 89.4 dB

– We worked closely with Impregnation Services’ engineers to design a custom enclosure using the SE Series as a starting point, we created a soundproof kit tailored to fit the machine while allowing easy access for maintenance and operation.

2. Prototyping and Testing:

– A prototype of the soundproof enclosure was built and installed around the dot peen machine.

– Initial tests showed a promising reduction in noise to 68.5 dB, but there were opportunities for further improvement.

– Based on feedback from Impregnation Services and additional sound measurements, we adjusted the design, focusing on optimizing the sound-absorbing materials and the sealing mechanisms.

3. Final Implementation:

– After continuous development and testing, we successfully reduced the noise levels by 30 decibels to 59 dB.

– The final enclosure was integrated into Impregnation Services’ workflow with minimal disruption, and operators reported an immediate improvement in their working conditions.

Results:

The implementation of the SE Series with our Soundproofing Kit was a resounding success. The noise level of the dot peen machine was reduced by 30 decibels, bringing it within safe operating limits and significantly improving the overall work environment.

Key Outcomes:

– Enhanced Operator Safety: The reduction in noise levels created a safer work environment, protecting operators from potential hearing damage and reducing fatigue.

– Improved Productivity: With the noise issue resolved, operators were able to focus better on their tasks, leading to increased productivity.

– Employee Satisfaction: The quieter environment contributed to higher job satisfaction among operators, who appreciated the investment in their well-being.

-Cleaner work environment: Helps keep swarf inside enclosure and protects operator and operation from debris.

Conclusion:

The collaboration between Impregnation Services and our team resulted in a successful solution that not only met but exceeded the noise reduction goals. The SE Series Soundproof Kit proved to be an effective and adaptable solution, demonstrating our commitment to providing high-quality products that address real-world challenges.

Impregnation Services now operates with greater confidence, knowing their employees are working in a safer and more comfortable environment. This case study underscores the possibilities of innovative soundproofing solutions in industrial settings and our capability to deliver them.